Capabilities and Expertise in Custom Rubber Manufacturing #

Zong Yih Rubber Taiwan stands as a trusted partner for businesses seeking specialized, custom-molded rubber parts. With a focus on precision, quality, and adaptability, our company delivers tailored solutions for a wide range of industries and applications.

Comprehensive Customization for Rubber Parts #

We offer complete customization for rubber and rubber-metal parts, addressing every aspect of production:

- Size and Material Selection: Flexible to your specifications.

- Inspection and Traceability: Rigorous quality checks and full traceability.

- Packaging and Labeling: Solutions tailored to your logistics and branding needs.

Advanced Manufacturing Infrastructure #

Located in Taichung City, our facilities include three modern plants equipped for high-capacity, quality-driven production. Key highlights of our infrastructure:

- 64 Production Machines: Supporting a variety of molding processes, including injection and compression molding.

- Non-Wastage Material Machines: Six dedicated machines to maximize efficiency and minimize material waste.

- Large-Scale Production Capability: A 1000-ton compression molding machine for parts up to 1x1 meter, and a 15,000cc injection molding machine capable of injecting up to 18kg per shot for high-volume runs.

Product Range #

Our expertise covers a broad spectrum of custom-molded rubber products, each designed to meet specific industry requirements. Explore some of our featured custom products below:

Suspension Systems

Suspension Systems

Silent Block Rubber Bushing

Silent Block Rubber Bushing

Rubber Buffers

Rubber Buffers

Hollow Rubber Springs

Hollow Rubber Springs

Rubber Grip

Rubber Grip

Rubber Bumper

Rubber Bumper

Rubber Bellows

Rubber Bellows

Rubber Brake Cup

Rubber Brake Cup

Rubber Hose Elbow

Rubber Hose Elbow

Rubber Diaphragm Seals

Rubber Diaphragm Seals

Custom Rubber Seals/Gaskets

Custom Rubber Seals/Gaskets

Rubber Grommets

Rubber Grommets

Rubber V-ring

Rubber V-ring

Idler Drive Wheel

Idler Drive Wheel

Duckbill Check Valve

Duckbill Check Valve

Hydraulics Valve Packing

Hydraulics Valve Packing

RC Tyres

RC Tyres

Rubber Oil Hand Pump

Rubber Oil Hand Pump

Rubber Coupling

Rubber Coupling

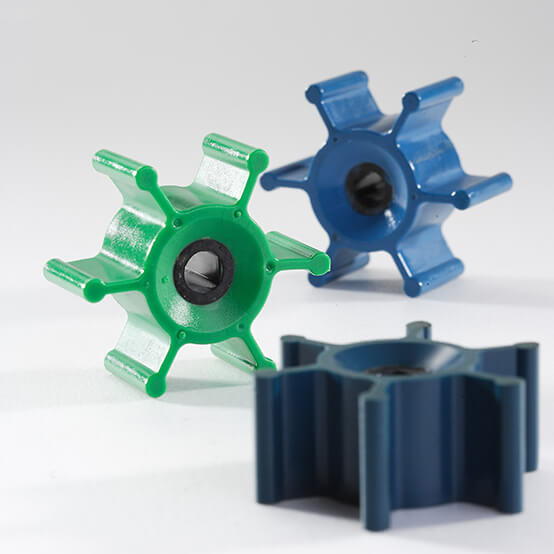

Rubber Impeller

Rubber Impeller

Research, Design, and Quality Assurance #

Our professional Research and Development team is central to our operations, designing intricate tooling and innovating to meet complex client requirements. Their expertise ensures that even the most demanding specifications are translated into practical, high-performing rubber components.

Quality is at the core of our process. Every product undergoes thorough inspection by our Quality Assurance department before leaving our facilities, ensuring compliance with both customer and industry standards.

Industries and Applications #

Our custom-molded rubber parts serve a diverse array of industries, including:

- Automated Industrial Equipment

- Manual and Pneumatic Tools

- Packaging

- Toys and Model Car Tires

- Food and Beverage

- Home Appliances

- Sporting Goods

- Bicycles

- Building and Construction

- Agriculture

- Piping and Drainage

- Semiconductors

- New Energy Technologies

- Electronics

- Military

- Automotive, Aviation, Marine, and Railway Transportation

Connect With Us #

For more information or to discuss your custom rubber part requirements, contact us. We are committed to supporting your projects with expertise, reliability, and a partnership approach.